Defence placement a time of discovery

University student Charli Goodrich contributed to several forensic analysis projects during her 12-month placement with Defence.

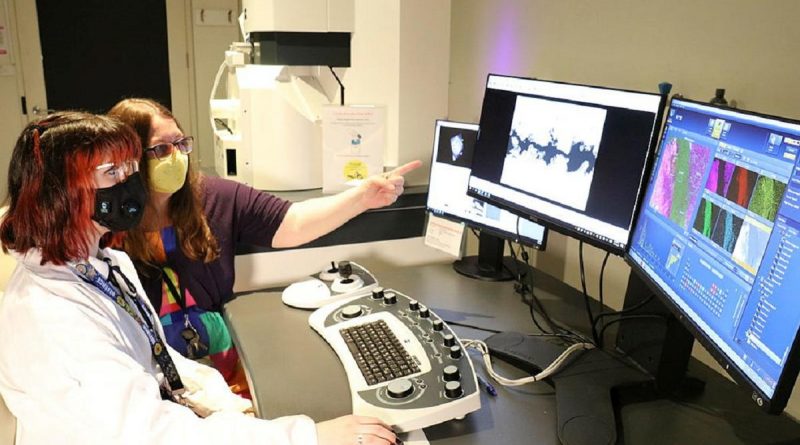

CAPTION: Defence Science and Technology Group scientist Sonya Slater, right, shows university student Charli Goodrich how to use equipment used in forensic analysis during Ms Goodrich’s 12-month placement at Fishermans Bend, Victoria. Story by David Kilmartin.

Ms Goodrich is a third-year Bachelor of Science student majoring in chemistry at Swinburne University of Technology.

“I’ve learned things in the past 12 months that I would never have had the opportunity to learn anywhere else, and, for that, I feel extremely fortunate and grateful,” Ms Goodrich said during her recent summary presentation at DSTEM 2022, Defence’s annual science, technology, engineering and maths (STEM) student conference.

One of the projects she contributed to during her placement was the forensic analysis of a weld failure in an aircraft afterburner liner.

“That analysis involved assessing the damage to a small section of a repaired afterburner liner using different techniques to investigate the possible causes of the failure,” Ms Goodrich said.

“I was fortunate to be placed with supervisors Dr John Thornton and Sonya Slater, who are involved in many different projects, and, being a real-world office environment, learnt that it is important to be flexible and contribute to the tasks at hand.”

Ms Goodrich began her industry experience placement (IEP) with the analysis of hot corrosion damage, which is an accelerated oxidation process, to Air Force gas turbine blades.

That project was put on the backburner when the more time-sensitive forensic weld analysis task came along.

The process of afterburning temporarily supplements an aircraft’s thrust without the need for a larger engine.

The afterburner flame can reach temperatures greater than 1700 degrees Celsius as it burns extra fuel and oxygen to increase the temperature of the exhaust and thus the aircraft velocity.

This high-stress environment often leads to cracking and corrosion.

“The afterburner sample we received was a small, rectangular section cut from the liner, with a cracked weld repair down the middle of it,” Ms Goodrich said.

“Our task was to work out why the repair hadn’t lasted.

“This involved me taking overview images, conducting surface analysis using DSTG’s [Defence Science and Technology Group] scanning electron microscope [SEM], including energy dispersive X-ray spectroscopy, and eventually dissecting the sample to examine cross-sections along the crack.”

The team’s analysis showed significant cracking throughout the weld.

According to Ms Goodrich, the destructive testing was crucial to discovering why the braze, or the join, had failed.

It also helped reveal several other weld non-conformities.

During Ms Goodrich’s placement, Dr Thornton, Ms Slater and colleagues trained her in the use of scientific equipment, such as the SEM, to analyse the topography and composition of samples, as well the techniques of forensic photography and optical microscopy, which are important for capturing images of samples before and during destructive analysis.

“In preparing to use the SEM, I learnt how to clamp and dissect samples, set them in resin, polish them and gold-plate them with a sputtering machine to make them conductive [necessary for samples that are to be scanned],” she said.

“I even had the opportunity to go to the Australian Synchrotron with John to analyse samples in the imaging beamline.”

The Australian Synchrotron produces powerful beams of light that are used at individual experimental facilities to examine the molecular and atomic details of a wide range of materials.

A time slot was booked at the synchrotron for Ms Goodrich to examine a sample of the gas turbine blade with the beam of light.

Dr Thornton said the diffraction pattern from the surface allowed an analysis of what effect the dirt and corrosion were having on the turbine.

Ms Goodrich said she was thankful for the placement.

“As a chemistry major, I had to study engineering and materials science concepts in order to fully understand my placement tasks,” she said.

“Thankfully, I had knowledgeable scientists around me who were always ready to answer my questions and explain new concepts.

“I thoroughly enjoyed my time as an IEP student here at DSTG.

“Working in material science has further fostered my interest in inorganic chemistry and I look forward now to exploring this further in the remainder of my degree and in my career.”

.

.

.

.